0 ratings0% found this document useful (0 votes)

2 viewsTopic 2.0 PLC System

Topic 2.0 PLC System

Uploaded by

hoseah mwanzahCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Topic 2.0 PLC System

Topic 2.0 PLC System

Uploaded by

hoseah mwanzah0 ratings0% found this document useful (0 votes)

2 views53 pagesOriginal Title

Topic 2.0 Plc System

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views53 pagesTopic 2.0 PLC System

Topic 2.0 PLC System

Uploaded by

hoseah mwanzahCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 53

MUKURWE-INI TTI

ELECTRICAL AND ELECTRONICS ENGINEERING

DEPARTMENT

DIPLOMA IN ELECTRICAL &

ELECTRONICS ENGINEERING (POWER

OPTION)

Topic 2. PLC Systems

INTRODUCTION

PLC is a unit of hardware used to control and automate

industrial processes.

It is a micro-computer based controller that uses stored

instructions in programmable memory to implement logic,

sequencing, timing, counting and arithmetic functions through

digital or analog input/output modules, for controlling

machines and processes.

The term logic is used because programming is primarily

concerned with implementing logic and switching

operation.

The PLC is designed as replacement for the hard-wired

relay and timer logic to be found in traditional control

panels, where PLC provides ease and flexibility of control

based on programming and executing logic instructions.

A PLC has three main aspects: the inputs and

outputs and the control program.

The input is anything that can sense the status of the

environment and then convert that information in to a

signal.

Often the signal can simply be a voltage that is either on or

off.

For example, input devices can be proximity switches,

photoelectric sensors, temperature sensors, push buttons, or

pressure sensors.

The outputs are connected to the devices that need to

be controlled like motors, indicator lights, fans,

warning sirens or heating elements.

Control processes need devices to monitor events

or measure needed values.

These devices are generically called inputs to the PLC.

The program uses a set of logical instructions that

drives the outputs based on the inputs.

THE NEED FOR PLCS

Hardwired panels were very time consuming to wire,

debug and change.

The PLCs eliminates much of the hard wiring that was

associated with conventional relay control circuits.

PLCs have the great advantage that the same basic

controller can be used with a wide range of control

systems.

PLCs require shorter installation and commissioning

times than do hard-wired systems .

To modify a control system and the rules that are to be

used, all that is necessary is for an operator to key in a

different set of instructions. There is no need to rewire.

The result is a flexible, cost effective, system which can be

used with control systems which vary quite widely in their

nature and complexity.

PLCs are similar to computers but whereas computers are

optimized for calculation and display tasks, PLCs are

optimized for control tasks and the industrial environment.

Thus PLCs have specific features suited for industrial

control :-

Rugged and designed to withstand vibrations, temperature,

humidity and noise

Modular plug-in construction, allowing easy replacement or

addition of units (e.g. input/output);

Standard input/output connections and signal levels

Have interfacing for inputs and outputs already inside the

controller.

Easily understood programming language which is

primarily concerned with logic and switching

operations

Ease of programming and reprogramming in-plant;

Capable of communicating with other PLCs,

computers and intelligent devices;

Competitive in both cost and space occupied with

relay and solid-state logic systems.

These features make programmable controllers

highly desirable in a wide variety of industrial-

plant and process-control situations.

PLC ADVANTAGES

Flexibility: One single PLC can easily run many machines.

Correcting Errors: With PLC control, any change in circuit design

or sequence is as simple as retyping the logic. Correcting errors in

PLC is extremely short and cost effective.

Space Efficient: Today's PLC memory is getting bigger and bigger

this means that we can generate more and more contacts, coils,

timers, sequencers, counters and so on. It is possible to have

thousands of contact timers and counters in a single PLC.

Low Cost: Prices of PLC vary from few hundreds to few thousands.

Testing: A PLC program can be tested and evaluated in a lab. The

program can be tested, validated and corrected saving very valuable

time.

Visual observation: When running a PLC program a visual

operation can be seen on the screen. Hence troubleshooting a circuit

is really quick, easy and simple.

TYPICAL PLC APPLICATIONS

PLCs are used to operate greenhouse irrigations systems.

PLCs are used for sorting packages on a conveyor by

operating a diverter.

PLCs are implemented in a variety of control operations

from large to small. Carwashes are a popular use for PLCs

because it involves intricate use of sensors and motors, but

also has the need for relatively complex logic.

Lumber mills use PLCs to control the main saw and

loading of wood while various sensors ensure safe

operation so that people and equipment are not harmed

PLCs can withstand the harsh condition desert conditions

while controlling an oil recovery process.

PLC ARCHITECTURE

There are two types:

Open architecture design allows the system to be

connected easily to devices and programs made by

other manufacturers.

Closed architecture or proprietary system is one

whose design makes it more difficult to connect

devices and programs made by other manufacturers.

NOTE: When working with PLC systems that

are proprietary in nature you must be sure that

any generic hardware or software you use is

compatible with your particular PLC.

PLC HARDWARE

The structure of a PLC can be divided several

parts/components.

The main parts are input/output modules, central processing

unit, memory and programming terminal.

Processor unit or central processing unit

(CPU) is the unit containing the microprocessor

and this interprets the input signals and carries

out the control actions, according to the program

stored in its memory, communicating the

decisions as action signals to the outputs.

Memory unit is where the program is stored that

is to be used for the control action to be exercised

by the microprocessor and data stored from the

input for processing and for the output for

outputting

Input and output (I/O) modules – are where the

processor receives information from external devices

and communicates information to external devices.

The I/O unit provides the interface between the system

and the outside world, allowing for connections to be

made through I/O channels to input devices such as

sensors and output devices such as motors and solenoids.

It is also through the I/O unit that programs are entered

from a program panel.

Every I/O point has a unique address which can be used

Input and output (I/O) devices - is collection of

physical elements of the control system that either

provide or use I/O data.

Programming device / terminal are used to enter

the required program into the memory of the

processor.

The program is developed in the device and then

transferred to the memory unit of the PLC.

Rack Assembly: Most medium to large PLC

systems are assembled such that the individual

components - CPU, I/O, power supply - are

modules that are held together within a rack.

In smaller PLC systems - all of these components may

be contained in a single housing or "brick" - these

smaller systems are sometimes referred to as "bricks"

or "shoebox" PLCs.

Power supply unit is needed to convert the

mains A.C voltage to low d.c. voltages necessary

for the processor and the circuits in the input end

output interface modules.

Communication interface is used to receive and

transmit data on communication network from or

to other remote PLC.

It is concurred with such actions as device

verification, data acquisition, synchronization

between user applications and connection

management.

PLC CPU ARCHITECTURE

The CPU controls and supervises all operations

within the PLC, carrying out programmed

instructions stored in the memory.

An internal communications highway, or bus

system, carries information to end from the CPU,

memory and I/O units, under control of the CPU.

The CPU controls and processes all the operation

within the PLC. It is supplied with a clock with a

frequency of between 1 and 8 MHz.

This frequency determines the operating speed of

the PLC and provides the timing and

The information within the PLC is carried by

means of digital signals.

The internal paths along digital signal flow are

called buses.

A bus is just a number of conductors along which

electrical signals can flow.

The internal structure of the CPU depends on the

microprocessor concerned

The simplified model consist of five parts ALU,

CU, Registers, Buses, and memory.

Arithmetic and Logic Unit (ALU) Which is

responsible for data manipulation and carrying out

arithmetic operations of addition and subtraction

and logic operations of AND, OR, NOT and

EXCLUSIVE – OR(X-OR).

It receives control signals from the control unit telling it

to carry out these operations

Control Unit – This controls the movement of

instruction in and out of the processor and also

controls the operation of ALU.

It consists of a decoder, controls logic circuit and a

clock to ensure everything happens at the correct time.

It is also responsible for performing the instruction

execution cycle.

Registers – located within the microprocessor and

used to store information involved in program

execution.

It is a small amount of internal memory that is used for the

quick storage and retrieval of data and instructions.

All processors include some common registers used for

specific functions, namely the program counter, instruction

register, accumulator, memory address register and stack

pointer.

Bus - Buses are the paths used for communication

within the PLC.

The information is transmitted in binary form i.e. as a

group of bits with a bit being a binary digit of 0 or 1.

System bus is used for communication between the I/O ports and

I/O unit.

It is a cable which carries data communication between the major

components of the computer including the microprocessor.

Control bus carries the signals relating to the control and co-ordination

of the various activities across the computer which can be sent from the

control unit within the CPU.

It informs memory devices whether they are to receive data from an input or

output data and to carry out timing signals used to synchronize actions.

Data bus carries the data used in the process carried out by the CPU.

It is used for the exchange of data between the processor, memory and

peripherals, and is bidirectional.

A micro processor termed as being 8-bit has an internal data bus which can

handle 8-bit number.

Address bus is used to carry the addresses of memory location.

It contains the connection between the microprocessor and memory that carry

the signals relating to the addresses which the CPU is processing at that time,

such as the locations that the CPU is reading from or writing to.

Memory: - There are several memory elements in a PLC

system.

Executive memory or operating system memory which is read only

memory (ROM) to give permanent storage for operating system and

fixed data used by the CPU.

It is the one that actually does the scanning in the PLC.

System memory – in order for the operating system to function, a

section of the memory is allotted for system administration.

As the executive program performs its duties, it often requires a place to

store intermediate results and information.

A section of RAM (Random Access Memory) is installed for this purpose.

Data memory – This is a RAM where information is stored on the

status of input and output devices and the values of timers and

counters and other internal devices.

Data RAM is sometimes referred to as data table or register table.

User program memory – The final area of memory in a PLC is

allocated to the storage of the user program.

It is this memory area that the executive program instructs the micro-

I/O status memory or I/O image table. A

portion of RAM is allocated for the storage of

current I/O status.

Every single I/O module has been assigned to a

particular location within the I/O image table.

The location within the input and output image

table/map are identified by addresses, each location

has its own unique address.

MEMORY ORGANIZATION

This refers to how certain areas of memory in a PLC

are utilized.

Physical addressing is the ability to read data from a

specific module terminal or write information to a

specific module terminal.

During the execution of user program, the micro

processor scans the user program and interprets the

user command, when information is read from a

contact or input, it is stored in memory.

This portion of memory is the input image table/map

which is designated to store this input information.

Each input typically has at a minimum, a single bit

Data resulting from logical analysis by the CPU

i.e. various output device status generated during

the execution of user program is stored in

memory labeled as the output image table/map

From this point, the information is transferred to

a designated output module and then to a

particular field device.

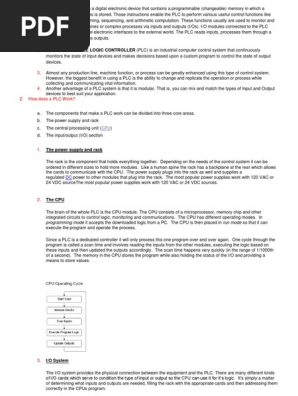

BASIC PLC OPERATION

A PLC works by continuously running a program

that checks the inputs and then updates the outputs.

The process of the PLC running throughout its

program is called scanning.

Scanning speed depends on the program size and

execution time.

The total time for a PLC to check the inputs, run

the program and update the outputs is called the

cycle time.

Typical cycle times are 10 ms to 100 ms.

Every cycle the inputs are check and saved to

memory.

Then the program is run using the status of the

saved inputs.

After the program is done the outputs are updated

and the cycle starts again.

SCANNING PROCESSES

The PLC’s CPU monitors the status of all inputs.

It takes these values and energizes or de-

energizes the outputs according to the ladder

diagram / user program.

This is referred to as Scanning.

The CPU of the PLC executes the user program

over and over again when it is in the run mode.

A scan does not consist of a PLC executing

ladder diagram rung by rung, but instead the PLC

performs an I/O and program scan.

The I/O scans transfers data to and from the output and

input modules respectively.

The information is transferred in the form of bits and

stored in image tables (image maps) are block of

memory designated to store the input and output bit

state)

The input and output is the portion of the PLC that

interfaces with the outside world.

The actual bridge between the physical world and

internal world of the PLC is the optical isolation

circuitry.

There are four basic steps in the operation of all

PLCs; input scan, program scan, output scan,

and house keeping.

These steps continually take place in a repeating

loop.

Input scan: During the input scan, the current status

of every input module is stored in the input image

(memory) table, bringing it up-to-date.

Thus all the status of the input devices (which in turn is

connected to the input module) is updated in the input

memory table.

Program scan: Following the input scan, the CPU enters its

user program execution, or program scan.

The execution involves starting at the program's first instruction,

then moving on to the second instruction and carrying out its

execution sequence.

This continues to the last program instruction.

Throughout the user-program execution, the CPU continually

keeps its output image (memory) table up-to-date.

Output scan: During program scan, the output modules

themselves are not kept continually up to date.

Instead, the entire output image table is transferred to the output

modules during the output scan which comes after the program

execution.

Thus the output devices are activated accordingly during the

output scan

Housekeeping – these steps includes

communication with programming, internal

diagnostic activities etc.

PLC INPUT AND OUTPUT (I/O) DEVICES

Input/output (I/O) is information representing the

data that is received from senses elements / devices

and the commands that are sent to actuating and

indicating devices.

The I/O system is collection of physical elements of

the control system that either provide or use I/O data.

The term sensor is used for an input device that

provides a usable output in response to a specified

physical input.

For example, a thermocouple is a sensor which converts a

temperature difference into an electrical output.

The term transducer is generally used for a device that

converts a signal from one form to a different physical

form.

Thus sensors are often transducers, but also other devices

can be transducers, e.g. a motor which converts an electrical

input into rotation.

The number of I/O devices used within a control system

is called its point count.

Thus the total number of digital and analog point is used to

give an indication of the size of a control system.

PLC has input and output lines through which is

connected to a system it directs.

Any electrical signal processing always requires a voltage

supply (an active part) and a load (passive part) or vice versa.

I/O modules connect "real world" field devices to the

controller.

They convert the electrical signals used in the field devices

into electronic signals that can be used by the control system,

and translate real world values to I/O table values.

I/O modules communicate with PLC CPU in one of three

ways:

Backplane - The I/O modules can be located in the same rack or

station. Communications then takes place within the rack or across

the backplane.

Backplane extension - backplane extension modules allow I/O

modules to be located in racks or stations which are separated from

the controller.

Device network - modules can communicate with a controller over

a network. Industrial networks are used to interconnect field level

devices with controllers. Common IO networks are FieldBus,

Profibus, and DeviceNet.

There are major types of I/O

Analog – continuous devices that sense and respond to a

range of values

Digital – binary devices which must be in one of only two

states on or off.

ANALOG INPUT AND OUTPUT DEVICES

Analog input devices senses continuous

parameters common analog inputs are pressure,

temperature, speed transducers etc.

An analog input card converts a voltage by

current leg or signal that can be anywhere from 0

to 20mA) into digitally equivalent number that

can be understood by the CPU.

To input an analog voltage (into a PLC or any

other computer) the continuous voltage value

must be sampled and then converted to a

numerical value by an A/D converter.

The process of sampling the data is not instantaneous, so

each sample has a start and stop time.

The time required to acquire the sample is called the sampling

time. A/D converters can only acquire a limited number of

samples per second.

The time between samples is called the sampling period T, and the

inverse of the sampling period is the sampling frequency (also

called sampling rate).

The sampling time is often much smaller than the sampling period

Analog output devices respond to a range of output values

from the controller common analog output signals include

motor speed, valve position, air pressure etc.

An analog output card will convert a digital number sent by

the CPU to its real world voltage or current.

Analog device data requires significantly more manipulation

and processing then digital device data.

DIGITAL INPUT AND OUTPUT DEVICES

Inputs come from sensors that translate physical

phenomena into digital signal.

Thus digital input devices may be either on or

off, they may not hold any other value.

Common digital field input devices include push

buttons, unit switches and photo eyes.

Digital output devices are devices which give

either on or off.

Common types are relays, motor starter, solenoid

valves etc.

EXAMPLES OF INPUTS AND OUTPUTS

Inputs for a PLC come in a few basic varieties the

simplest are AC and DC inputs.

Examples of input devices are:

Proximity switches – use inductance, capacitance or

light to detect an object logically

Switches – mechanical mechanisms will open or close

electrical contacts for a logical signal

Potentiometer – measures angular position

continuously using resistance.

LVDT (Linear variable differential transformer) –

measures linear displacement continuously using

magnetic coupling.

Outputs to actuators allow a PLC to cause something to happen

in a process.

Outputs from PLC are often relays, but they can also be solid

state electronics such as transistors for DC output or TRIACs

for AC outputs.

Continuous output requires special output cards with digital to

analog converters.

Examples are:

Solenoid valves – logical output that can switch a hydraulic or

pneumatic flow

Lights – logical output that can often be powered directly from PLC

output boards

Motor starters – motors often draw a large amount of current when

started, so they require motor starters which are basically large relays.

Servo motors – a continuous output from the PLC can command a

variable speed or position.

ACTIVE AND PASSIVE INPUTS/OUTPUTS

Active I/O are those inputs or outputs which have the

power source and are referred to as having a current

source or voltage source (sourcing)

Passive I/O are those inputs or outputs which do not

have power source and acts as the load or current sink

(sinking)

SOURCING AND SINKING

Sourcing and sinking are used to describe the

way in which d.c devices are connected to a PLC

and uses d.c currents and voltages.

Sourcing – When active, current flows from

supply, through the use a single supply voltage.

With sourcing, using the conventional current flow

direction as from positive to negative, an input device

receives current from the input module i.e. the input

module is the source of the current (Fig a)

If the current flows from the output module to an

output load then the output module is referred as to

sourcing (fig b)

Sinking- when active the output allows current to

flow to a common ground.

This is best selected when different voltages are

supplies.

With sinking, using the conventional current flow direction

from positive to negative, our input device supplies current

to the input module i.e. the input module is the sink for the

current (fig a)

If the current flows to the output module from an output

load then the output module is referred to as sinking (fig b)

TYPICAL CONNECTIONS OF PLC

TYPES OF PLC SYSTEM

The PLC sizes are given in terms of program memory

size and the maximum number of I/O points the

system can support.

However to evaluate properly any PLC, consideration

is taken for many additional features such as its

processor, cycle time, language facilities, functions

expansion capability etc.

PLC size Max I/O point User memory size

defined (No. of instructors)

Small 40/40 1k

Medium 128/128 4k

Large >128/>128 >4k

Small PLC – small and mini PLCs are designed as robust, compact

units which can be mounted on or beside the equipment to be

controlled.

They are mainly used to replace hard wired logic relays, timers, counters etc

that control individual items of plant or machinery, but can also be used to

co-ordinate several machines working in conjunction with each other.

Programming is by way of logic instruction list (mnemonic) or relay ladder

diagrams.

Medium-sized PLC: - In this range, modular construction

predominates with plug-in modules on rack mounting system or

Back plane system.

This allows the simple upgrading or expansion of the system by fitting

additional 1/0 cards into the racks

Large PLC - where control is very large numbers of input and output

points is necessary or complex control functions are required, a large

PLC is selected.

It is designed for use in large plants or machines requiring continuous

control.

They are also employed as supervisory controllers to monitor and control

PLC STYLES OF CONSTRUCTION

The main styles are unitary, modular and rack mounting.

Unitary PLC - is the smallest and least expensive.

It contains every feature of a basic system in one box and is attached to

the machine being controlled.

They are not expandable so the application is limited to on-board I/O.

Modular – These are a range of modules that slot together to

build up a system.

Basic modules are the power supply, the main module containing the

CPU, the input module and the output module.

Modular PLCs are used in applications where a higher I/O count is

needed or when using specialty modules such as quadrature encoders.

They may be designed to be fixed direct to a back panel.

Usually they are arranged on a rack or rail and mounted inside a large

cabinet for protection and security.

The main advantage is that the number of input and output terminals

can be expanded to cope with changes to the hardware system.

Rack mounting – are usually more expensive,

expandable and powerful than modular PLC.

The rack provides a power and communication backplane that

greatly increases the communication rate between the

processor and the modules as well as allowing some specialty

modules to communicate with each other without the

processor.

The number of available 1/0 points is also much higher in the

rack systems.

END

You might also like

- ANALYTICAL CHEMISTRY Supplement With SolutionsDocument26 pagesANALYTICAL CHEMISTRY Supplement With Solutionsanon_5859936100% (4)

- Conveyor Control Using Programmable Logic ControllerDocument7 pagesConveyor Control Using Programmable Logic ControllerdanwNo ratings yet

- Programmable Logic Controllers (PLC) : Powerpoint Presentation OnDocument17 pagesProgrammable Logic Controllers (PLC) : Powerpoint Presentation OnSumanAgarwal100% (1)

- Ee415 LT 1Document19 pagesEe415 LT 1ehero33gNo ratings yet

- Programmable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Document5 pagesProgrammable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Danelle GeamalaNo ratings yet

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- Chapter 1 NotesDocument3 pagesChapter 1 Noteshero_spaceboy3600No ratings yet

- PLCDocument31 pagesPLC01parthNo ratings yet

- Industrial Automation - Final PDFDocument153 pagesIndustrial Automation - Final PDFTanvir KhanNo ratings yet

- IA Lab Experiments AllDocument47 pagesIA Lab Experiments Allraj251003No ratings yet

- PLCDocument39 pagesPLCVishwadhar ShreedharNo ratings yet

- Introduction To PLCDocument59 pagesIntroduction To PLCAbdisa BegnaNo ratings yet

- Industrial AutomationDocument72 pagesIndustrial AutomationmahderNo ratings yet

- What Is PLCDocument8 pagesWhat Is PLCkunjiayman2No ratings yet

- PLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionDocument35 pagesPLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionjustinkikoNo ratings yet

- PLCDocument78 pagesPLCAbid ParwezNo ratings yet

- Tutorial On PLCDocument33 pagesTutorial On PLCmanojnancyNo ratings yet

- Programmable Logic ControllerDocument23 pagesProgrammable Logic Controllergebrerufael hailayNo ratings yet

- PLC Basics Tutorial: What Is A PLC?Document6 pagesPLC Basics Tutorial: What Is A PLC?nov17muraliNo ratings yet

- Nns Notes Ie PLCDocument13 pagesNns Notes Ie PLCNarendra SinhaNo ratings yet

- Complete Report1 PLCDocument90 pagesComplete Report1 PLCRao Arslan Rajput100% (3)

- PLCDocument36 pagesPLCsonhack96No ratings yet

- Programmable Logic Controller and Its ApplicationsDocument5 pagesProgrammable Logic Controller and Its Applicationssumit100% (1)

- PLC DdcmisDocument63 pagesPLC DdcmisNicole LeeNo ratings yet

- Een 11 Finals Lec3Document16 pagesEen 11 Finals Lec3lavadiajhonNo ratings yet

- Programmable Logic ControllerDocument25 pagesProgrammable Logic Controllermanoj4sivaNo ratings yet

- Introduction To PLCsDocument42 pagesIntroduction To PLCsArun Kumar Yadav100% (1)

- What Is Programmable Logic ControllerDocument4 pagesWhat Is Programmable Logic ControllerNgwe Soe HanNo ratings yet

- Lecture 2 - PLC and SCADA IntrductionDocument17 pagesLecture 2 - PLC and SCADA IntrductionDilip Kumar JenaNo ratings yet

- Industrial Control System IDocument28 pagesIndustrial Control System IIsaac KimaruNo ratings yet

- Applications of PLCDocument23 pagesApplications of PLCJyoti Prakash Naik100% (1)

- Programmable Logic ControllerDocument29 pagesProgrammable Logic ControllerGiovan George MendezNo ratings yet

- PLC Based Sequential Batch Process CONTROL System1Document27 pagesPLC Based Sequential Batch Process CONTROL System1Ritesh Vaishnav100% (1)

- Mechatronics (302050) Lecture Notes / PPT Unit IvDocument63 pagesMechatronics (302050) Lecture Notes / PPT Unit IvSwapvaib100% (1)

- PLCDocument13 pagesPLCChalez ZengeretsiNo ratings yet

- PLC Interview QuestionsDocument4 pagesPLC Interview QuestionsShashikant PrasadNo ratings yet

- PLC and Its ApplicationsDocument63 pagesPLC and Its ApplicationsAmit YadavNo ratings yet

- PLC and DdcmisDocument63 pagesPLC and DdcmisSiddharth Tiwari100% (1)

- EJ501 T3 PLC IntroductionDocument44 pagesEJ501 T3 PLC IntroductionLoga HSNo ratings yet

- Programmable Logic ControllerDocument5 pagesProgrammable Logic ControllerShah JayNo ratings yet

- Industrial AutomationDocument16 pagesIndustrial Automationvivek6681No ratings yet

- 04 - Step by Sptep Procedure For The Usage of Crouzet Millenium 3 PLC With ExercisesDocument225 pages04 - Step by Sptep Procedure For The Usage of Crouzet Millenium 3 PLC With Exercises447 KusumanjaliNo ratings yet

- Programmable Logic Controller: Need For PLCDocument20 pagesProgrammable Logic Controller: Need For PLCmkumar_234155No ratings yet

- Report On PLCDocument17 pagesReport On PLCRahul SaxenaNo ratings yet

- Chapter 3 Introduction To PLC SystemDocument26 pagesChapter 3 Introduction To PLC SystemMuhammad AniqNo ratings yet

- PLC Workshop 1-2 DayDocument120 pagesPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- Assignment A PCIDocument20 pagesAssignment A PCISanjay SundaralingamNo ratings yet

- PLC HandbookDocument51 pagesPLC HandbookRushabh Gohil100% (1)

- PLC Technical DefinitionDocument6 pagesPLC Technical DefinitionKyle EmersonNo ratings yet

- PLC - Logic GatesDocument14 pagesPLC - Logic GatesAakash VirdheNo ratings yet

- Introduction To PLCDocument29 pagesIntroduction To PLCAkhilesh JainNo ratings yet

- PLC and PLC TechnologiesDocument28 pagesPLC and PLC Technologieskatjinomasa kavetuNo ratings yet

- Answers To Question-2Document350 pagesAnswers To Question-2Dev KumarNo ratings yet

- PLC BasicsDocument53 pagesPLC Basicsssservice centreNo ratings yet

- PLC 1Document27 pagesPLC 1Juan Sánchez LópezNo ratings yet

- PLC QuestionsDocument17 pagesPLC QuestionsbahyNo ratings yet

- Implementation of Home Automation Safety Control Using Programmable Logic ControllerDocument10 pagesImplementation of Home Automation Safety Control Using Programmable Logic ControllerAnjaneyulu NaikNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- How To Speed Read Piano Chord SymbolsDocument23 pagesHow To Speed Read Piano Chord Symbolsdgathis86% (14)

- K.S. School of Engineering and Management, Bangalore - 560109Document2 pagesK.S. School of Engineering and Management, Bangalore - 560109Pradeep BiradarNo ratings yet

- The Effect of Information Technology, Employee Profesinalism, and Supervision To The Improvement of Employee PerformanceDocument4 pagesThe Effect of Information Technology, Employee Profesinalism, and Supervision To The Improvement of Employee PerformanceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Operator Training Simulator For Windows: User's GuideDocument26 pagesOperator Training Simulator For Windows: User's GuidejjhenNo ratings yet

- Lab Report IV Characteristics of DiodeDocument5 pagesLab Report IV Characteristics of DiodeAamir AliNo ratings yet

- Polar Coordinates Packet 2012Document42 pagesPolar Coordinates Packet 2012Titser LaarniNo ratings yet

- 2 El Tensor de TensiónDocument59 pages2 El Tensor de TensiónMartínCiezaNo ratings yet

- Aspire TC-780 Desktop Computer Service GuideDocument138 pagesAspire TC-780 Desktop Computer Service GuideWarapot WongsiriNo ratings yet

- Periodic Properties of The Elements 608817Document3 pagesPeriodic Properties of The Elements 608817Kumar nayakNo ratings yet

- PCM AnalyzerDocument2 pagesPCM Analyzeramr_karimmNo ratings yet

- Impeller Velocity TrianglesDocument2 pagesImpeller Velocity TrianglesLorettaMayNo ratings yet

- High Resolution Sequence Stratigraphy: Innovations, Applications and Future ProspectsDocument9 pagesHigh Resolution Sequence Stratigraphy: Innovations, Applications and Future ProspectsNEHEMIAH DOMINICKNo ratings yet

- German V. Canibas Jr. 8 - Rizal 1. Reflexive Property of EqualityDocument45 pagesGerman V. Canibas Jr. 8 - Rizal 1. Reflexive Property of EqualityDanilo Fronda Jr.No ratings yet

- TRM CATALOGUE 08 Planning Transport and InstallationDocument40 pagesTRM CATALOGUE 08 Planning Transport and InstallationMilos Petrovic100% (1)

- Construction and Building MaterialsDocument7 pagesConstruction and Building MaterialsFábio FriolNo ratings yet

- Hydraulic Jack Research Paper PDFDocument5 pagesHydraulic Jack Research Paper PDFgatewivojez3100% (1)

- Air and Gas Drying With Axsorb Activated Alumina-English PDFDocument11 pagesAir and Gas Drying With Axsorb Activated Alumina-English PDFNathalia DelgadoNo ratings yet

- MAD Chapter 4Document61 pagesMAD Chapter 4Shaikh WasimaNo ratings yet

- Din 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Document3 pagesDin 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Mohammed EljammalNo ratings yet

- Epro Services, System III - MBBDocument2 pagesEpro Services, System III - MBBBaugh Graphic DesignNo ratings yet

- TOS EsP 6 1st Quarter 2022 2023Document10 pagesTOS EsP 6 1st Quarter 2022 2023denmarkNo ratings yet

- TACP-1008d LGWsDocument133 pagesTACP-1008d LGWsCharles Cousineau100% (2)

- Green HSR Reliable Communication With LTE-R Using MIMO-DPDDocument13 pagesGreen HSR Reliable Communication With LTE-R Using MIMO-DPDAnonymous iQMzYrNo ratings yet

- Quantitative and Qualitative Research SummaryDocument10 pagesQuantitative and Qualitative Research SummaryPeregrin TookNo ratings yet

- Chemistry 12 How Do You Find The Ion Concentration in A Tap Water SampleDocument5 pagesChemistry 12 How Do You Find The Ion Concentration in A Tap Water SampleToxicBlueNo ratings yet

- General Mathematics: Quarter 1 - Module 3Document31 pagesGeneral Mathematics: Quarter 1 - Module 3Chris Toph MaldicasNo ratings yet

- Tips For Writing SQL QueryDocument12 pagesTips For Writing SQL QueryAbhishekNo ratings yet

- Soal Latihan I (5 - )Document2 pagesSoal Latihan I (5 - )Syaiful AnwarNo ratings yet

- Contoh Soalan Pengurusan PembelajaranDocument10 pagesContoh Soalan Pengurusan PembelajaranthinaNo ratings yet