Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Uploaded by

Jessica VargasCopyright:

Available Formats

Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Uploaded by

Jessica VargasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical Specifications

Uploaded by

Jessica VargasCopyright:

Available Formats

HYDRAULIC CALCULATIONS OF WET STANDPIPE SYSTEM AND TECHNICAL SPECIFICATIONS

PROPOSED THREE (3) STOREY APARTMENT

DESIGN DATA : Light Hazard

SYSTEM TYPE : Wet Stand Pipe

DENSITY (gpm/ft²) : 0.15

AREA APPLICATION ft²(m²) : 5431(504)

HOSE STREAMS, gpm(lpm) : 100(378)

TOTAL WATER REQ'D, : 100(379)

gpm(lpm)

CALCULATION DATA:

Type of Building Structure : Three (3) Storey

Occupancy Classification : Light Hazard

Elevation of Building : 10.5 m. (34.44 ft.)

Pump Room Location : Ground Floor

Fire Reserve Tank Location : Ground Floor

Tank Capacity : 6,000 Gals

Fire Sprinkler Time Duration : 30-60 minutes

Tank Dimension : 2.75m x 2.75m x 3.5m

1 FIRE HOSE CABINET

1.1 Fire hose cabinet shall be fully recessed. Frame shall be gage 18 steel with white interior

and red exterior enamel paint finish over primer. Door frame shall be aluminum.

1.2 Unit shall be consist of the following:

One (1) - 40mm x 30 M single jacket hose with brass coupling.

One (1) - 40mm combination fog and solid stream nozzle, brass.

One (1) - Semi-Automatic rack, brass finish and hose nipple.

One (1) - 40mm angle valve, brass finish.

One (1) - Spanner wrench

One (1) - 4.5kg dry chemical fire extinguisher. Class ABC, UL/FM

One (1) - Fire Ax

1.3 Fire hose cabinet shall be subject to the approval of the Architect and the Owner.

2 FIRE DEPARTMENT CONNECTIONS

2.1 Type - Threaded type, to match the local Fire Department requirement

2.2 Pressure rating - 1200 KPa

2.3 Finish - rough brass

2.4 Uses and sizes:

Fire Hose valve - 65mm male connection

Fire department connection - 100 x 65 x 65 mm female connection

2.5 All Fire Department connections shall be provided with brass caps, chains and brass signs.

3 SIGNS

3.1 Identification signs shall be provided as required by NFPA codes or as shown on the drawing.

3.2 Identification signs shall have red background and white letters and letters sizes that are easily

readable.

4 MATERIALS (CPVC & BI PIPING)

4.1 Type - CPVC Pipes (Cold Fusion Jointing)

4.2 Minimum wall thickness - schedule 40

4.3 Type - BI Joints - Threaded joints for pipe sizes 50mm and smaller; Welded or flanged joints for pipe

sizes 65mm and bigger.

4.4 Fittings - Malleable iron ANSI B16.3 for threaded fittings; steel ANSI B16.5 for welded fittings and

steel flanges.

4.5 Valves - Bronze ASTM B62, 1200KPa for sizes 50mm and smaller; All iron, bronze fitted, 1200KPa for

sizes 65mm bigger. UL Listed/FM approved.

4.6 Pipe Sealant - Teflon tape for threaded joints and 3mm rubber gasket for flange joints.

4.7 All pipes embedded underground shall have at least two (2) coats of tar or asphalt and wrapped

with approved pipe wrapping tape or jute sack.

4.8 Application - Standpipe and sprinkler pipes.

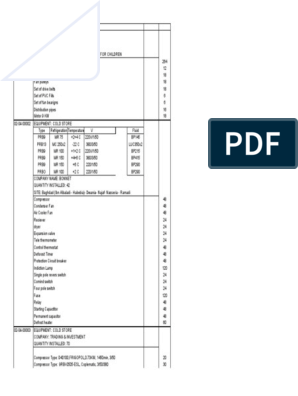

PIPE

FITTING FLOW PRESS.

NODE SECTION PARTICULARS COMPUTATIONS (GPM) (PSI)

LENGTH

(FT.)

WSPR

1 ELEVATION

100Ø - BI PIPE

10.5m. X 3.28 = 34.44 ft. 34.44 34.44 ft. x 0.433 = 14.91 14.91

INSIDE HOSE

2 NON-SPRINKLER FLOW 100 65

STREAM

TOTAL DYNAMIC

100 79.91

HEAD

FIRE PUMP AND JOCKEY PUMP SCHEDULE

TOTAL FLOW REQUIREMENT (GALLONS PER MINUTE) 100

TOTAL DYNAMIC HEAD REQUIRED (PSI) 79.91

FIRE PUMP:

TOTAL FLOW RATE : 100 GPM

TDH : 79.91 PSI X 2.31 = 184.59 ft

GPM X TDH

HP =

3960 X 0.55

100 X 184.59

HP =

3960 X 0.55

HP = 8.47 HP APPROXIMATELY 10 HP

USE : 10 HP WATER PUMP (WET STAND PIPE)

@ 100 GPM, 60 MINUTES SUPPLY,

6000 gals. TANK CAPACITY

ITEM DESCRIPTION UNIT QUANTITY

1.0 MOBILIZATION / DEMOBILIZATION lot 1.0

SITE SUPERVISION lot 1.0

Sub-total for General Requirements

2.0 WET STANDPIPE SYSTEM

FIRE HOSE CABINET set 3.0

FIRE DEPARTMENT CONNECTION set 1.0

BI PIPE SCH. 40

BI PIPE SCH. 40 3" length 5.0

BI PIPE SCH. 40 2" length 9.0

BI FITTINGS

EQUAL TEE 1" pc 2.0

TEE REDUCER 3" X 2" pc 2.0

3.0 PUMP ROOM VALVES

CHECK VALVES 3" pcs 1.0

GATE VALVE 3" pcs 1.0

GATE VALVE 3" pcs 1.0

FOOT VALVE 3" pcs 1.0

PRESSURE SWITCH pcs 2.0

PRESSURE RELIEF VALVE pcs 1.0

4.0 PUMPS

FIRE PUMP, 1 PHASE, 150GPM, 10HP, 100PSI set 1.0

ELECTRICAL WIRING set 1.0

5.0 MISCELLANEOUS WORKS

CONSUMABLES lot 1.0

HANGERS & SUPPORTS lot 1.0

4.0 LABOR, EQUIPMENTS AND FABRICATION lot 1.0

TESTING & COMMISSIONING lot 1.0

CONTROL PANEL & ACCESSORIES lot 1.0

WATER FLOW SWITCH set 1.0

FITTING AND CONSUMABLES lot 1.0

You might also like

- Fire Pro QuotationDocument3 pagesFire Pro QuotationIan Lester Toledo100% (4)

- FSMR FormatDocument7 pagesFSMR Formatian007papagNo ratings yet

- ASCOTT Fire Protection BOQDocument3 pagesASCOTT Fire Protection BOQJonathan FerueloNo ratings yet

- BFP Smoke Control SystemDocument135 pagesBFP Smoke Control SystemMike100% (2)

- Fire Pro SpecsDocument11 pagesFire Pro Specscoolth2No ratings yet

- NEW PRICELIST 2022-Viking Sprinkler New PricelistDocument3 pagesNEW PRICELIST 2022-Viking Sprinkler New PricelistJV Balisi100% (1)

- Honda CR V 2007 2009 Heating Repair ManualDocument7 pagesHonda CR V 2007 2009 Heating Repair Manualdana100% (55)

- PME Engineering ReportDocument28 pagesPME Engineering Reportnaruto256100% (2)

- Detailed Cost Estimate Smoke ControlDocument2 pagesDetailed Cost Estimate Smoke ControlNB CCNo ratings yet

- 04 05 PME Write ShopDocument3 pages04 05 PME Write Shopjamil diligNo ratings yet

- Bldg. 42 Fire Sprinkler System DesignDocument70 pagesBldg. 42 Fire Sprinkler System DesignJohn A. Ceniza100% (1)

- Sprinkler CalculationDocument3 pagesSprinkler CalculationMiguel Angel Carcamo Ordaz100% (2)

- 6000 Gals. Ugt Detail Underground Tank Detail: Proposed Gazz Dampol Ii-B, PulilanDocument1 page6000 Gals. Ugt Detail Underground Tank Detail: Proposed Gazz Dampol Ii-B, Pulilanshad cambaNo ratings yet

- Mechanical and Ventilation System SpecificationsDocument7 pagesMechanical and Ventilation System SpecificationsDCMS CONSTRUCTIONNo ratings yet

- Hydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGDocument9 pagesHydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGRhowelle TibayNo ratings yet

- Falar III Requirement For Zpi Phils IncDocument3 pagesFalar III Requirement For Zpi Phils IncRobert Ulatan50% (2)

- Fire Pro Scope of WorkDocument2 pagesFire Pro Scope of Workshem1767% (3)

- Nfpa 14 Standpipes & Hose Valves: Presented by American Fire Sprinkler AssociationDocument34 pagesNfpa 14 Standpipes & Hose Valves: Presented by American Fire Sprinkler Associationhesham3bbasNo ratings yet

- Labor Rate For Ducting WorksDocument1 pageLabor Rate For Ducting Worksbhh0% (1)

- Fire Pro Design ComputationDocument6 pagesFire Pro Design ComputationAlvin Cris RongavillaNo ratings yet

- FFP Basi Calculation For Pump Amp Tank Selection CompressDocument28 pagesFFP Basi Calculation For Pump Amp Tank Selection CompressSopheareak ChhanNo ratings yet

- Sprinkler SystemDocument16 pagesSprinkler SystemNethaji100% (1)

- Ra 8495 ClarificationsDocument17 pagesRa 8495 Clarificationsqweqweqweq qweasdqwedqweqwNo ratings yet

- 2023 CCAC Pricelist - February 1, 2023Document8 pages2023 CCAC Pricelist - February 1, 2023Raylie PaguioNo ratings yet

- SPEC For Chilled Water Pipework and FittingsDocument4 pagesSPEC For Chilled Water Pipework and FittingsonspsnonsNo ratings yet

- Mechanical PlansDocument1 pageMechanical PlansYesTaratNo ratings yet

- Design Installation Operation and Maintenance of Fire Sprinkler System Me421Document87 pagesDesign Installation Operation and Maintenance of Fire Sprinkler System Me421John Daniel100% (3)

- 03-2 PSME Code On Fire ProtectionDocument23 pages03-2 PSME Code On Fire ProtectionDessa GuditoNo ratings yet

- Quotation For Icct Cainta Sprinkler SystemDocument2 pagesQuotation For Icct Cainta Sprinkler SystemMark Anthony JerezNo ratings yet

- Guide To Professional Mechanical Engineering ApplicationDocument2 pagesGuide To Professional Mechanical Engineering ApplicationJoemar AnchetaNo ratings yet

- FHC & Accessories GiacominiDocument4 pagesFHC & Accessories GiacominiBdSuliano100% (1)

- LPG 106 Schematic Diagram Gas LayoutDocument1 pageLPG 106 Schematic Diagram Gas Layoutkhawaldeh jamal0% (1)

- Fire Protection BomDocument5 pagesFire Protection BomDoroty CastroNo ratings yet

- Fire Protection-Sprinkler Sys (With Min Press 7psi) & Water Supply Sys (042114)Document2 pagesFire Protection-Sprinkler Sys (With Min Press 7psi) & Water Supply Sys (042114)Edwin TorilloNo ratings yet

- Cesar PmeDocument20 pagesCesar PmeFrancis Michael JacintoNo ratings yet

- 2021 - Bi Fittings Welded NPDocument5 pages2021 - Bi Fittings Welded NPmarvinNo ratings yet

- Boston Bay Exhaust & Ventilating FansDocument4 pagesBoston Bay Exhaust & Ventilating FansGem EscalanteNo ratings yet

- Smoke Control System DesignDocument4 pagesSmoke Control System DesignHermi David100% (1)

- Role of MEs - 2019Document16 pagesRole of MEs - 2019Rogelio S. ManingdingNo ratings yet

- Basic High Rise BLDG DesignDocument107 pagesBasic High Rise BLDG DesignMichael SaavedraNo ratings yet

- Engineering Report For Single Pass Rice Mills/ Corn Mills: General InformationDocument2 pagesEngineering Report For Single Pass Rice Mills/ Corn Mills: General InformationPrincess SalvadorNo ratings yet

- Presentation ME Career Progression by Jerico T. BorjaDocument42 pagesPresentation ME Career Progression by Jerico T. BorjaDidy RobotIncorporated0% (1)

- Large Floor Standing (Daikin)Document6 pagesLarge Floor Standing (Daikin)Melvin MhdsNo ratings yet

- BOQ Format - Fire Pro PDFDocument6 pagesBOQ Format - Fire Pro PDFKurama BasketNo ratings yet

- Carrier Crystal InverterDocument3 pagesCarrier Crystal Inverterver_at_workNo ratings yet

- Design of An Air-Conditioning and Ventilation System in A 1,300 M Three-Storey HospitalDocument16 pagesDesign of An Air-Conditioning and Ventilation System in A 1,300 M Three-Storey HospitalSecret SecretNo ratings yet

- General Specification Mechanical Works-URDANETA PROJECT ONE CATUBACDocument8 pagesGeneral Specification Mechanical Works-URDANETA PROJECT ONE CATUBACmichael ongNo ratings yet

- Carrier Wrac Brochure PDFDocument36 pagesCarrier Wrac Brochure PDFkhraieric16100% (1)

- FDAS InterfacingDocument14 pagesFDAS InterfacingRenzer NeznerNo ratings yet

- School Design MechanicalDocument1 pageSchool Design MechanicalWilbert Reuyan0% (1)

- Tds Epocoat MB WhiteDocument3 pagesTds Epocoat MB WhitefcdorupaNo ratings yet

- Dry Stand Pipe Riser Diagram Conn. 3: Pendent Sprinkler HeadDocument1 pageDry Stand Pipe Riser Diagram Conn. 3: Pendent Sprinkler HeadNathaniel Gutierez MangubatNo ratings yet

- Proposal For Bank-MGDocument7 pagesProposal For Bank-MGRanjit Roy100% (1)

- Project Title: Automatic Fire Sprinkler System Location: Total Project Cost: 624,043.09Document6 pagesProject Title: Automatic Fire Sprinkler System Location: Total Project Cost: 624,043.09Reynaldo PesqueraNo ratings yet

- Bill of Quantities - Feb29Document15 pagesBill of Quantities - Feb29Elmer Soroan BarrerasNo ratings yet

- PriceList Firefly LED Price List April 2019 IssueDocument16 pagesPriceList Firefly LED Price List April 2019 IssuePrime ElectromotorsNo ratings yet

- 02 - Sprinklers & Hose Cabinets CalculationsDocument3 pages02 - Sprinklers & Hose Cabinets Calculationskdpmansi100% (1)

- NiagaraDocument45 pagesNiagaraMike BongolanNo ratings yet

- NATAAircraft Hangar Fire Protection GuidanceDocument5 pagesNATAAircraft Hangar Fire Protection GuidanceFurkan KadıNo ratings yet

- Specifications For Sprinkler System Installation in Esep BuildingDocument25 pagesSpecifications For Sprinkler System Installation in Esep BuildingCrystian Kobee EmpeynadoNo ratings yet

- Pump Calculations & Tank Sizing NotesDocument6 pagesPump Calculations & Tank Sizing NotesBrighton MsonzaNo ratings yet

- Basic Vocational Knowledge Electrical Installation PDFDocument150 pagesBasic Vocational Knowledge Electrical Installation PDFaimizaNo ratings yet

- Chapter 5 - PLC Application in The IndustryDocument32 pagesChapter 5 - PLC Application in The IndustryMOHD SABREENo ratings yet

- Basics of ElectronicsDocument15 pagesBasics of ElectronicsAtul KumarNo ratings yet

- Transmisor de Posicion Tp290meDocument44 pagesTransmisor de Posicion Tp290meTntNo ratings yet

- Kas 150 PDFDocument11 pagesKas 150 PDFvladimir2426No ratings yet

- Plano 7Document1 pagePlano 7Nicolas PaezNo ratings yet

- 903 064 2 BetonfilterpresseDocument2 pages903 064 2 BetonfilterpresseJohn Walker BrownNo ratings yet

- 02 04Document131 pages02 04hjmmNo ratings yet

- A4-P 2.0 enDocument2 pagesA4-P 2.0 enAtiq Ur RehmanNo ratings yet

- Ecart Stock UpdatedDocument3 pagesEcart Stock UpdatedIcu-asu FamNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-ShiftDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-ShiftJorge GallardoNo ratings yet

- Epson Inkjet PrinterDocument6 pagesEpson Inkjet PrintergovindarajnmcaNo ratings yet

- Astrophotography Nightscape Lens RatingDocument26 pagesAstrophotography Nightscape Lens RatingnetsurfoNo ratings yet

- R-102 DSDocument4 pagesR-102 DSSimone DoeNo ratings yet

- 'ROMA' Fig. 160-2 Pressure Relief Valve With CapDocument2 pages'ROMA' Fig. 160-2 Pressure Relief Valve With CapPhilNo ratings yet

- Endstops - Marlin FirmwareDocument9 pagesEndstops - Marlin FirmwareKurniawan SusiloNo ratings yet

- WO 2053 Handling Sec 5-1 Electric Diagram PreliminaryDocument245 pagesWO 2053 Handling Sec 5-1 Electric Diagram PreliminaryMinh TrầnNo ratings yet

- USER MANUAL - 4 IN 1 LED PAR LIGHTgDocument8 pagesUSER MANUAL - 4 IN 1 LED PAR LIGHTgSbl LightningNo ratings yet

- Carlyle 104mm Screw-RefrigDocument37 pagesCarlyle 104mm Screw-RefrigMiguel Ángel Puche Morales100% (1)

- Catalogo Kaeser AcumuladoresDocument5 pagesCatalogo Kaeser AcumuladoresFernando GómezNo ratings yet

- Manual Winchester Mp4 Winchester Air RDocument17 pagesManual Winchester Mp4 Winchester Air RYuyNo ratings yet

- Littelfuse ProtectionRelay ER 15KV PDF DiagramDocument1 pageLittelfuse ProtectionRelay ER 15KV PDF DiagramBenjamín Cares ZalazarNo ratings yet

- PVTRIN Training Course: Troubleshooting GuideDocument20 pagesPVTRIN Training Course: Troubleshooting GuideBeni Saputra100% (1)

- Scan 1200 XT Service Manual 2end Pages V 1.0Document15 pagesScan 1200 XT Service Manual 2end Pages V 1.0Silverio SogorbNo ratings yet

- Telescopic Loading Bellows: ZG - ZHDocument6 pagesTelescopic Loading Bellows: ZG - ZHalexandroNo ratings yet

- Appendix 12 Fire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder InstallationsDocument25 pagesAppendix 12 Fire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder InstallationsAadil KhoodoruthNo ratings yet

- MP02 0742 13 ISO 2902 - Rev.B1Document44 pagesMP02 0742 13 ISO 2902 - Rev.B1PradeepNo ratings yet

- Spesifikasi Boom Truck SS3506Document2 pagesSpesifikasi Boom Truck SS3506Regi HermawanNo ratings yet

- Title 1678109374126Document210 pagesTitle 1678109374126Aishwarya S HiremathNo ratings yet