ESP Run Life Prediction

ESP Run Life Prediction

Uploaded by

azareiforoushCopyright:

Available Formats

ESP Run Life Prediction

ESP Run Life Prediction

Uploaded by

azareiforoushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ESP Run Life Prediction

ESP Run Life Prediction

Uploaded by

azareiforoushCopyright:

Available Formats

Continuous ESP insulation resistance monitoring using ACE ESP sensors will

help predict and extend ESP run life.

ACE ESP downhole sensor uses continuous ESP insulation resistance measurement

technique to predict and extend ESP run life. It is a true measurement technique to arrive at the

insulation resistance reading; providing a reverse DC Voltage and measuring the current to arrive

at the resistance.

Other brands of ESP sensors use current leakage, which is not a true measurement

technique. Rather they measure the current supplied by the surface read out unit and compare it to

current measured downhole by the sensor, and assume the difference is current leakage.

Unfortunately, this is not an accurate measurement, since there are so many measurement

inaccuracies between the surface and downhole equipment, due to downhole temperature changes,

induced noise from VSD’s and motor cables introducing more errors.

Some ESP sensors can only take a current leakage reading during the power-up, so

although the display may show a reading shortly after power-up, the same reading will still be on

the display months or years later. The measurement cannot be taken again so even if the cable has

been shorted for months the incorrect reading is still displayed.

These flaws render current leakage measurement useless for ESP performance analysis.

ESP insulation resistance, on the other hand, gives a reliable trend for ESP run life predication.

Figure 1 below shows insulation resistance trend. On the day of the first ESP start-up the

insulation resistance measurement from ACE ESP sensor showed 10.234 MOhms, which

indicates a healthy ESP system. There was very little change in insulation resistance over the next

157 days of ESP operation. Finally, the trend showed a steep decline and on day 157 insulation

resistance reading was half the value of the one at the ESP start-up. It is an indication that ESP

electric system is weakening and the operator needs to prepare for an ESP failure. At this point, it

is recommended to slow down VSD in order to lower Voltage and harmonics in the system to

prolong ESP run life. It is also recommended to adjust VSD control set points such that unwanted

ESP shutdowns and re-starts are avoided.

A sharp drop in insulation resistance from MOhms to kOhms on day 164 indicates an

imminent ESP failure within a few days.

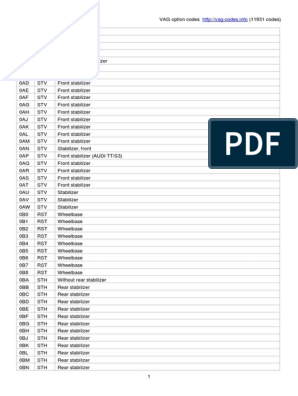

Figure 1.

ESP insulation resistance trend. Measurements taken automatically by ACE ESP sensor over 165

days

Resistance,

Days

MOhm

1 10.234

2 10.215

3 10.215

149 10.188

150 10.123

151 9.85

152 9.5

153 8.8

154 7.5

155 6.8

156 6.8

157 6.8

158 5.3

159 4.5

160 3.8

161 2.3

162 1.8

163 1.5

164 0.76

165 0.22

You might also like

- Drilling Supervisor Interview Questions PDFDocument2 pagesDrilling Supervisor Interview Questions PDFazareiforoush100% (10)

- MECH3410 Lab ReportDocument5 pagesMECH3410 Lab ReportNamit Jain0% (1)

- 45-Hour Parent/Teen Driving Guide: With Freedom Comes Great ResponsibilityDocument56 pages45-Hour Parent/Teen Driving Guide: With Freedom Comes Great Responsibilityjaya bersatuNo ratings yet

- Drill - Quiz 3Document2 pagesDrill - Quiz 3azareiforoushNo ratings yet

- Integrated Chassis ManagementDocument1 pageIntegrated Chassis ManagementOliver AlfaroNo ratings yet

- UntitledDocument4 pagesUntitledkhaledNo ratings yet

- Flow Rate Vs Pressure: Axis TitleDocument2 pagesFlow Rate Vs Pressure: Axis TitleAsasasNo ratings yet

- UPE Secpropsdimsprops Eurocode3 UK 16-11-2023Document8 pagesUPE Secpropsdimsprops Eurocode3 UK 16-11-2023Zack DaveNo ratings yet

- Vessel Lauching Air BagsDocument10 pagesVessel Lauching Air BagsAbdelrahmanNo ratings yet

- PowerTips - Motor Starting and Running Currents and Rating Guide PDFDocument14 pagesPowerTips - Motor Starting and Running Currents and Rating Guide PDFankur yadavNo ratings yet

- PowerTips - Motor Starting and Running Currents and Rating GuideDocument14 pagesPowerTips - Motor Starting and Running Currents and Rating Guideankur yadavNo ratings yet

- Vertical Turbine Fire Pump: Cul & Ul Listed & FM ApprovalDocument6 pagesVertical Turbine Fire Pump: Cul & Ul Listed & FM Approvaln.hartonoNo ratings yet

- Lab Report Marcet BoilerDocument8 pagesLab Report Marcet BoilerAnis Thuraiya100% (1)

- UPN Secpropsdimsprops Eurocode3 UK 4-24-2019Document8 pagesUPN Secpropsdimsprops Eurocode3 UK 4-24-2019harishram123456No ratings yet

- PH302 - Electrical Communication & Instrument: Experiment No: 5 Title: Heterodyne CircuitDocument11 pagesPH302 - Electrical Communication & Instrument: Experiment No: 5 Title: Heterodyne CircuitTerence CheonNo ratings yet

- Duct Calculation Fan BlowerDocument2 pagesDuct Calculation Fan Blowerabdul0rohiminNo ratings yet

- Mec Qty 088472 Rev.7 CO2 22-07-13Document3 pagesMec Qty 088472 Rev.7 CO2 22-07-13sanusiibrahimNo ratings yet

- 03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Document22 pages03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Anonymous oKTCFZNTmNo ratings yet

- Electric Motor Pump CurveDocument1 pageElectric Motor Pump CurveMd Nazrul Islam AzadNo ratings yet

- Experiment Number 1Document5 pagesExperiment Number 1haris shahNo ratings yet

- ZG EurusDocument12 pagesZG EurusRoberto SanchezNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485072082.xlsx Page 1 Sur 21Document21 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485072082.xlsx Page 1 Sur 21dsd sdsdNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485067870.xlsx Page 1 Sur 19Document19 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485067870.xlsx Page 1 Sur 19dsd sdsdNo ratings yet

- A-290 Wood Horn DrawingDocument3 pagesA-290 Wood Horn Drawingvugiaa9.creepNo ratings yet

- Mechanical Engineering Laboratory Report: Marcet BoilerDocument11 pagesMechanical Engineering Laboratory Report: Marcet BoilerSHADES 4 ALLNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Intervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialDocument7 pagesIntervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialCristian SantanderNo ratings yet

- Marcet Boiler Lab ReportDocument4 pagesMarcet Boiler Lab ReportJohnConor95% (41)

- Summary CT at Bare Flex 20240318Document27 pagesSummary CT at Bare Flex 20240318qc.vnc1No ratings yet

- Lab Example SEEBECKDocument4 pagesLab Example SEEBECKSneaKNo ratings yet

- FaitalPRO HF Comparison Table - MetricDocument7 pagesFaitalPRO HF Comparison Table - MetricMorgotNo ratings yet

- MU19 Pinos Elasticos Din 1481 Iso 8752 TecemDocument1 pageMU19 Pinos Elasticos Din 1481 Iso 8752 Tecemmugiwara ruffyNo ratings yet

- Sacred Sun SP Technical ManualDocument18 pagesSacred Sun SP Technical Manualمطابع رواسنNo ratings yet

- ArcelorMittal PV FR-De 2009-1Document45 pagesArcelorMittal PV FR-De 2009-1Oltean MariusNo ratings yet

- B750 VX-Series Performance DataDocument24 pagesB750 VX-Series Performance Datayogi wahyu pratamaNo ratings yet

- B750 VX-Series Performance DataDocument24 pagesB750 VX-Series Performance Datayogi wahyu pratamaNo ratings yet

- Steam Bench Apparatus ExperimentsDocument4 pagesSteam Bench Apparatus Experimentsحسين عمريNo ratings yet

- Voltage DropDocument5 pagesVoltage Dropahmed alhassanNo ratings yet

- Copper Nickel Metric Pipe StandardsDocument1 pageCopper Nickel Metric Pipe StandardsRahul JeganathanNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Document17 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Maheshwari TradersNo ratings yet

- Libre Sin AmortiguacionDocument13 pagesLibre Sin AmortiguacionF AGNo ratings yet

- Electrical TECHNICAL DATA BOOKDocument41 pagesElectrical TECHNICAL DATA BOOKsuhailkmNo ratings yet

- 2660/2680 SERIES: ModelsDocument4 pages2660/2680 SERIES: Modelssandra montesNo ratings yet

- A Copy of XT7 - EXTRUDER OUTPUT TESTDocument2 pagesA Copy of XT7 - EXTRUDER OUTPUT TESTAHMED YOUSEFNo ratings yet

- FT - XGQT01 - Codo 90°Document1 pageFT - XGQT01 - Codo 90°JoelCristhianVivancoCondeNo ratings yet

- Experiment No. - 05 Date: 12-02-24 Working With I To P and P To I Converters AIMDocument4 pagesExperiment No. - 05 Date: 12-02-24 Working With I To P and P To I Converters AIMMohd RehanNo ratings yet

- Cam AnalysisDocument7 pagesCam AnalysisSandeep Saini100% (1)

- Figure 02Document1 pageFigure 02Jerico LlovidoNo ratings yet

- Grade 80 Lifting Chain EN818-2Document1 pageGrade 80 Lifting Chain EN818-2Kitson RolinNo ratings yet

- Interpump Manual Serie 47Document20 pagesInterpump Manual Serie 47Komsan KasathumNo ratings yet

- Abb Metal SD (1tvs013166p0300) Rev1Document2 pagesAbb Metal SD (1tvs013166p0300) Rev1fakharkhiljiNo ratings yet

- CBR TestDocument3 pagesCBR TestAshutosh SharmaNo ratings yet

- Piping ChartDocument1 pagePiping ChartTrajko GjorgjievskiNo ratings yet

- PLVP-0308-007-2 Layconsa - Diagrama de Tuberías e Instrumentación (P & ID)Document1 pagePLVP-0308-007-2 Layconsa - Diagrama de Tuberías e Instrumentación (P & ID)kendy yalta chuquimbalquiNo ratings yet

- 1 in 60 Rule and Conversion Units 21 Oct 2022Document8 pages1 in 60 Rule and Conversion Units 21 Oct 2022Anand PanditNo ratings yet

- VIR, PVC Al CondrDocument1 pageVIR, PVC Al Condr01No ratings yet

- TS B3 SeriesDocument4 pagesTS B3 SeriesGuadalupe CondoriNo ratings yet

- Ee 404 Laboratory Experiment 4Document5 pagesEe 404 Laboratory Experiment 4andrei saadNo ratings yet

- Book 1Document2 pagesBook 1Ahmad AzriNo ratings yet

- Stainless Steel and Nickel Alloy Flanges: Engineering SuccessDocument4 pagesStainless Steel and Nickel Alloy Flanges: Engineering SuccessnknicoNo ratings yet

- NHD 150bar SeriesDocument4 pagesNHD 150bar Seriesnoha azamaliNo ratings yet

- Quiz 4 A-Choose The Correct Answer :: AnswersDocument2 pagesQuiz 4 A-Choose The Correct Answer :: Answersazareiforoush100% (1)

- Eni Saves 3 Months of Rig Time by Avoiding SidetrackDocument1 pageEni Saves 3 Months of Rig Time by Avoiding SidetrackazareiforoushNo ratings yet

- Drill - Quiz 2Document2 pagesDrill - Quiz 2azareiforoush100% (1)

- Engineer, Well Integrity (Operations)Document3 pagesEngineer, Well Integrity (Operations)azareiforoushNo ratings yet

- Pipesim Ukrgasvydobuvannya Ugv JSC Ukraine Cs PDFDocument2 pagesPipesim Ukrgasvydobuvannya Ugv JSC Ukraine Cs PDFazareiforoushNo ratings yet

- Drill - Quiz 1Document2 pagesDrill - Quiz 1azareiforoushNo ratings yet

- Long-Term Well Integrity: March 2014Document13 pagesLong-Term Well Integrity: March 2014azareiforoushNo ratings yet

- Creek UPM 18070 FinalDocument5 pagesCreek UPM 18070 FinalazareiforoushNo ratings yet

- Acid PerfTechDocument5 pagesAcid PerfTechazareiforoushNo ratings yet

- Case Study of Wireline Fishing - Hany MetwallyDocument5 pagesCase Study of Wireline Fishing - Hany Metwallyazareiforoush100% (1)

- Geomechanics Pinpoint Cause of Sand ProductionDocument2 pagesGeomechanics Pinpoint Cause of Sand ProductionazareiforoushNo ratings yet

- UPM-15040-Amin VFM PresentationDocument7 pagesUPM-15040-Amin VFM PresentationazareiforoushNo ratings yet

- Kabir UPM 18040 FinalDocument5 pagesKabir UPM 18040 FinalazareiforoushNo ratings yet

- P - Hyd. CalcDocument2 pagesP - Hyd. CalcazareiforoushNo ratings yet

- UPM-15070-Creek PresentationDocument18 pagesUPM-15070-Creek PresentationazareiforoushNo ratings yet

- Prosper To PIPESIMDocument1 pageProsper To PIPESIMazareiforoushNo ratings yet

- Surface Choke To Optimize Oil ProductionDocument7 pagesSurface Choke To Optimize Oil ProductionazareiforoushNo ratings yet

- Global Production Engineering ConsultingDocument2 pagesGlobal Production Engineering ConsultingazareiforoushNo ratings yet

- Honda Civic 1997 User and Maintenance Manual-2Document63 pagesHonda Civic 1997 User and Maintenance Manual-2wiliamhdez9999No ratings yet

- Improving Vehicle Handling Behaviour With Active Toe-ControlDocument100 pagesImproving Vehicle Handling Behaviour With Active Toe-ControlPCezzzNo ratings yet

- GWM Crash Test ResultsDocument5 pagesGWM Crash Test Resultsmick84No ratings yet

- Autopilot Technology in VehiclesDocument13 pagesAutopilot Technology in VehiclesMp RajanNo ratings yet

- Mazda6 GH BrochureDocument17 pagesMazda6 GH BrochureJorge Eliecer Acevedo SilvaNo ratings yet

- Vag Option CodesDocument177 pagesVag Option CodesKarniNo ratings yet

- Peugeot 2008 Prices and Specifications Brochure 1Document16 pagesPeugeot 2008 Prices and Specifications Brochure 1fruska999No ratings yet

- Spec #124 2021 Chevrolet Silverado 1500 (CC10753) 2WD Double Cab 147in Work TruckDocument8 pagesSpec #124 2021 Chevrolet Silverado 1500 (CC10753) 2WD Double Cab 147in Work TruckBibiNo ratings yet

- Toyota Hybrid PresentationDocument214 pagesToyota Hybrid PresentationRazvan Cristea100% (10)

- Hyundai VENUE SUV BrochureDocument10 pagesHyundai VENUE SUV BrochurespeedenquiryNo ratings yet

- Description: 2009 Chrysler Town & Country LX 2009 Chrysler Town & Country LXDocument41 pagesDescription: 2009 Chrysler Town & Country LX 2009 Chrysler Town & Country LXLarry Lawrence100% (1)

- Transporter Range BrochureDocument43 pagesTransporter Range BrochureSinqobile Sinoxolo Thembeka MsweliNo ratings yet

- ESP - How It WorksDocument5 pagesESP - How It WorksZvezdan DjurdjevicNo ratings yet

- 2005 Toyota Corolla BrochureDocument10 pages2005 Toyota Corolla Brochuremonlam100% (1)

- Peugeot 308 Prices and Specifications BrochureDocument12 pagesPeugeot 308 Prices and Specifications BrochureJason SmithNo ratings yet

- Vag Option CodesDocument257 pagesVag Option CodesLuk asNo ratings yet

- Ezu 2020 2 01Document4 pagesEzu 2020 2 01ANTONIO RUGAMANo ratings yet

- Nissan PATROL 2023 - Price List QatarDocument8 pagesNissan PATROL 2023 - Price List QatarghNo ratings yet

- Renault MasterDocument56 pagesRenault MasterDragan TorlakovicNo ratings yet

- Subaru XV GP Brochure 201211Document28 pagesSubaru XV GP Brochure 201211bg2491vxNo ratings yet

- 6 2Document206 pages6 2Eko hari PrasetyoNo ratings yet

- Sensotronic Brake Control (SBC) : Purpose and FunctionDocument2 pagesSensotronic Brake Control (SBC) : Purpose and FunctionChandan C RNo ratings yet

- Catalog Seres E1Document3 pagesCatalog Seres E1R MAXZNo ratings yet

- Subaru-Levorg 1.6 GTSDocument2 pagesSubaru-Levorg 1.6 GTSSeanNo ratings yet

- 2020 CorollaDocument9 pages2020 CorollaQasm Mikaeli0% (1)

- BMW 2series ActiveTourerDocument7 pagesBMW 2series ActiveTourerAdyBorsosNo ratings yet

- Operating Manual Smart ForfourDocument266 pagesOperating Manual Smart ForfourSumer SachirNo ratings yet

- Outlander Brochure PDFDocument12 pagesOutlander Brochure PDFMohammad Samir HassanNo ratings yet