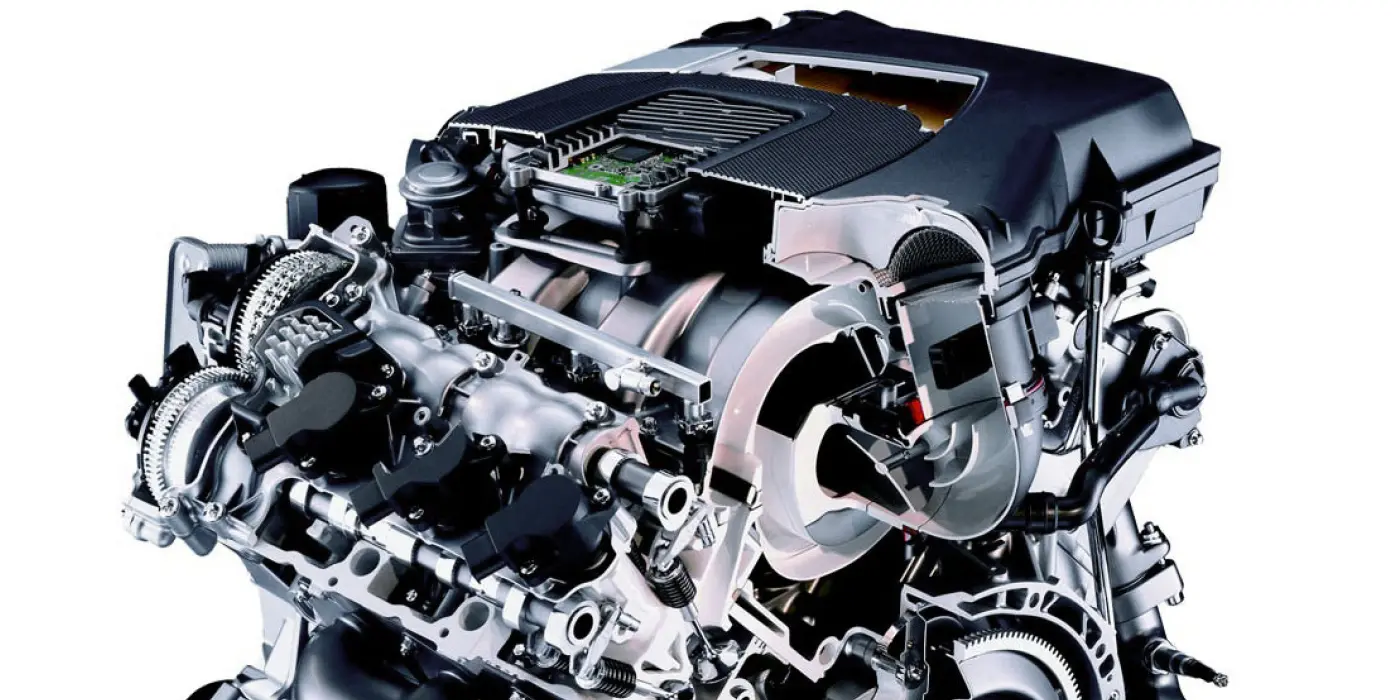

In 2008, Jaguar and Land Rover introduced the third generation of the AJ V8, or the AJ133. What set this 5.0L engine apart from the previous 4.0L and 4.2L versions was an increased displacement of five liters and direct injection. What makes this engine unique from other European V8s is the high-pressure fuel pumps are driven by the crankshaft using a chain that also turns the oil pump.

High-Pressure Pump

The AJ133 has two high-pressure fuel pumps mounted on the right-hand side of the engine block. The forward pump is number 1, and the rear pump is number 2. Each pump has a control valve that varies the fuel delivery amount by adjusting the timing of the engine.

The pressure relief valve protects the high-pressure side of the system from excessive pressure if there is a failure of the fuel metering valve. The nominal maximum operating pressure of the pumps is 2176 psi. The injectors deliver the fuel mass directly to the combustion chamber. The high-pressure fuel lines are connected together before they feed the right rail.

Tips

- Before any work is carried out on the high-pressure fuel system, the system must be depressurized. This can be performed with a scan tool to disable the in-tank pump and allowing the engine to run until it stops.

- The fuel pump fasteners must be tightened evenly and according to the service procedures. Failure to follow the set procedure will result in the mounting flange being stressed, which will lead to failure of the pump.

- To avoid unnecessary noise being transmitted to the cabin, the pumps are equipped with covers, which must always be refitted correctly, if removed.

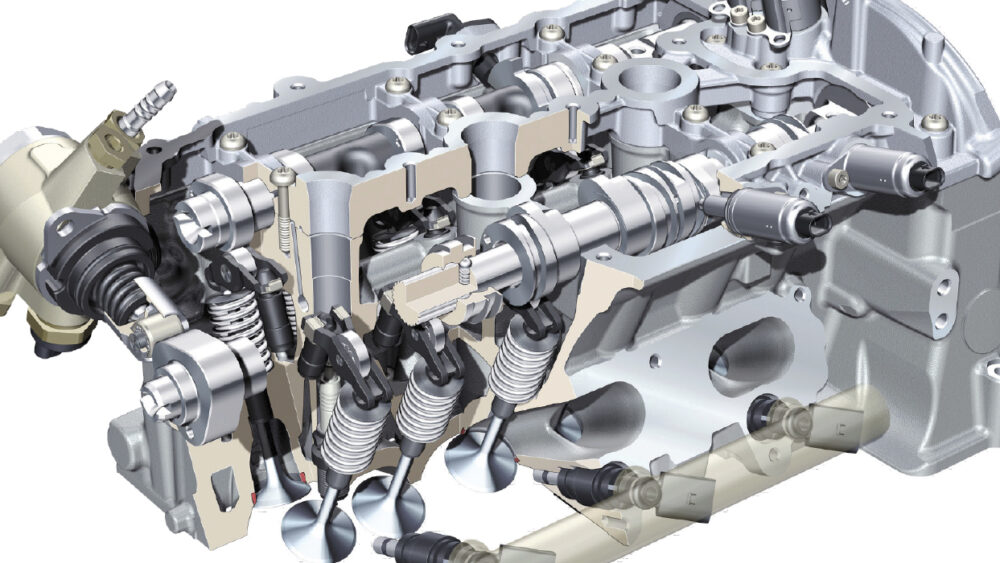

Injectors

The injectors are indexed like some spark plugs. The injectors have six spray beams. Two beams point below the spark plug, and the other four beams distribute fuel to the rest of the cylinder. The injectors operate using a two-stage power supply from the ECM. The initial trigger for the injectors is 65 volts. Once the trigger reaches a current level of 11 amps, the power supply is switched to battery voltage to keep the injector open.

more TIPS

- The Teflon seals must replaced if the injector is removed from the engine.

- Do not contaminate the Teflon seals with oil or grease to aid the assembly of the injectors to the engine.

- Always clean injector bores before fitting fuel injectors.

- The spark plugs should have been removed prior to pulling out the injectors with the slide hammer tool.

- Place a clean cap over the O-ring end of the injector to prevent contamination by dirt.

- The fuel rail and fuel injectors have built-in non-serviceable filters.

- Always reinstall injectors in the same location from which they were removed.

- If the fuel rails are removed, special tools must be used to align the fuel rail to injector when refitting. If this procedure is not carried out, the injector is then subjected to excessive side-loading which can cause the injector seal to become overheated.

In-Tank Pump

The AJ133 uses a returnless fuel system. The system pressure is maintained at a constant 59 psi. The fuel is supplied to the high-pressure fuel pumps from a fuel pump fitted within the fuel tank. Opening a vehicle door will cause the fuel pump relay to be activated for 3- to 5-seconds.

Common Problems

There are no major issues with the fuel system with either reported problems or TSBs. The only TSB for the fuels system warns about the use of low-quality fuels that lack enough detergent. While there have not been widespread reports of carbon deposits, regular induction cleaning services and in-tank treatments can reduce deposits on high-mileage engines.