Get the free 6s audit checklist

Show details

# of Y's:6S Checklist / 25 date:Sort (get rid of what's not needed): unnecessary items have been removed from the area (furniture, storage, things on walls)IN any incomplete work has been completed

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign 6s checklist form

Edit your 6s checklist template form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

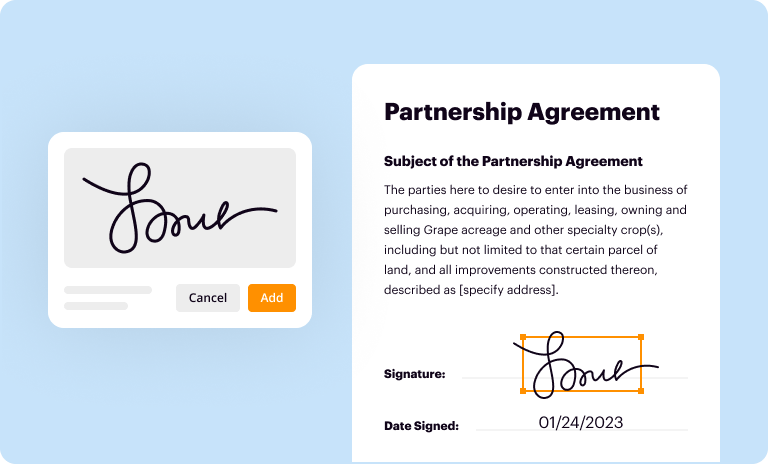

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

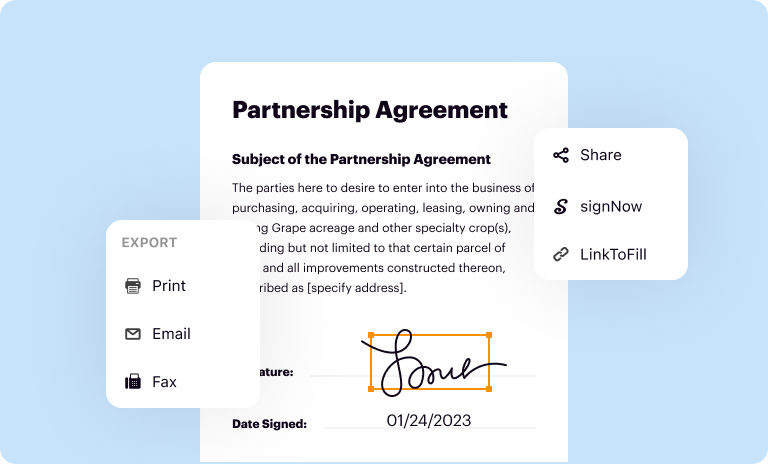

Share your form instantly

Email, fax, or share your 6s audit checklist excel form via URL. You can also download, print, or export forms to your preferred cloud storage service.

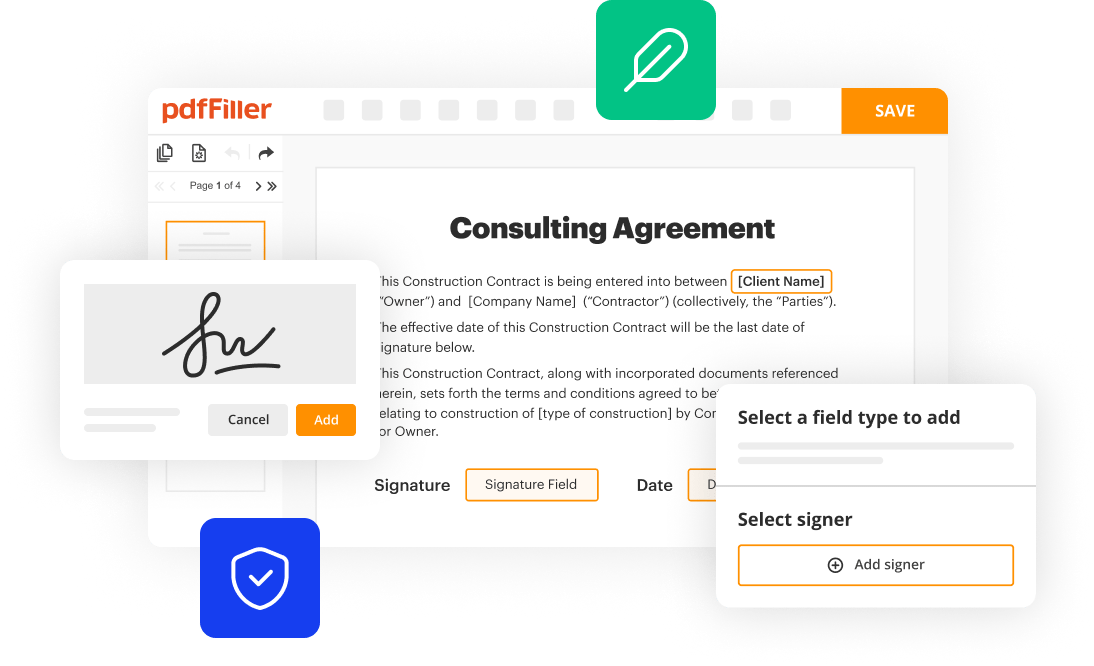

How to edit 6s audit checklist pdf online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit 6s daily checklist template form. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to work with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out 6s audit template form

How to fill out 6s checklist:

01

Start by gathering all necessary materials and resources for conducting the 6s checklist.

02

Begin the checklist by assessing the workplace for potential safety hazards and removing any unnecessary items or clutter.

03

Evaluate the layout and organization of the workspace, ensuring that everything is properly labeled and easy to access.

04

Clean and maintain the area, removing any dirt, dust, or debris that may be present.

05

Standardize procedures and processes to ensure consistency and efficiency within the workspace.

06

Sustain the improvements by regularly conducting inspections and audits to identify any areas that may need further attention.

Who needs 6s checklist:

01

Any organization or workplace that aims to improve safety, organization, and efficiency can benefit from implementing a 6s checklist.

02

Manufacturing plants, warehouses, hospitals, and offices are just a few examples of places where a 6s checklist can be utilized.

03

Employees, managers, and supervisors can all benefit from using a 6s checklist as it promotes a clean and organized work environment that enhances productivity and reduces accidents.

Fill

6s cleaning checklist

: Try Risk Free

People Also Ask about 6s audit scorecard

What are the 6S standards?

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.

What is an audit checklist?

An audit checklist may be a document or tool that to facilitate an audit programme which contains documented information such as the scope of the audit, evidence collection, audit tests and methods, analysis of the results as well as the conclusion and follow up actions such as corrective and preventive actions.

What are the 6S steps?

6S, a modification of the 5S methodology which includes "Safety" as the 6th S. It is a lean process improvement tool that stands for Sort, Set in Order (aka Straighten or Stabilize), Shine (aka Scrub or Sweep), Standardize, Sustain, Safety.

What should I look for in a warehouse audit?

You must look at analytics and documentation and observe operations in action. Speak with the workers who carry out each task. Ask them if they have noticed any inefficiencies, holdups, or areas where your processes could be improved.

How to do a 6S audit?

When performing a 6S audit, you will want to go through each of the different pillars of 6S and see how it is going. These pillars are Sort, Set, Shine, Standardize, Sustain, and Safety. Of course, you need to know the details of what each of these mean and how they should be implemented into your operations.

What is the 6S audit checklist for manufacturing?

A 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. It covers 6 key areas - Sort, Set in Order, Shine, Standardize, Sustain, and Safety - and helps identify areas for improvement.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Who is required to file 6s checklist?

The 6s checklist is typically used by managers and supervisors in order to ensure that their workplace is safe and organized. It is used to assess the 6 key areas of safety and organization, which are Sort, Set in Order, Shine, Standardize, Sustain and Safety. Generally, it is the responsibility of the manager or supervisor to ensure that the 6s checklist is completed.

How to fill out 6s checklist?

1. Identify the Problem: Start by identifying the problem that you are trying to solve.

2. Set Objectives: Set clear objectives and measurable targets for the project.

3. Establish Scope: Clarify the scope of the project, including what is in and out of scope.

4. Identify Resources: Identify the people, tools, and resources needed to complete the project.

5. Develop Plan: Develop a plan outlining how the project will be completed, including a timeline and budget.

6. Implement Plan: Implement the plan, making any necessary adjustments along the way.

7. Monitor Progress: Monitor the progress of the project, making sure it is staying on track.

8. Evaluate Results: Evaluate the results of the project to determine its success.

9. Document Results: Document the results of the project, including any lessons learned.

What is 6s checklist?

The 6S checklist is a tool used in Lean management methodologies, particularly in the manufacturing industry, to ensure workplace organization and cleanliness. It consists of six steps or categories that are essential for maintaining an efficient and safe work environment:

1. Sort: Eliminate any unnecessary items, tools, or materials from the workplace to reduce clutter and improve productivity.

2. Set in Order: Arrange and organize the remaining items and tools in an optimal manner. Assign designated locations for each item to ensure easy access and quick identification.

3. Shine: Clean the workplace thoroughly and regularly to eliminate dirt, dust, and hazards. Regular maintenance and cleaning routines should be established.

4. Standardize: Develop and implement standardized processes and best practices for organizing and cleaning the workspace. Create visual indicators or instructions to help employees maintain a consistent level of cleanliness and organization.

5. Sustain: Ensure that the 6S practices are continuously implemented and sustained over time. Provide regular training and reinforcement to employees to maintain the cleanliness and organization of the workplace.

6. Safety: Evaluate the workplace for potential safety hazards and implement measures to minimize or eliminate them. This includes implementing safety protocols, providing appropriate safety equipment, and continuously enforcing safe practices.

By following the 6S checklist, organizations can improve efficiency, reduce waste, enhance workplace safety, and create a more organized and productive work environment.

What is the purpose of 6s checklist?

The purpose of a 6S checklist is to ensure that a workplace is organized, clean, and efficient. 6S stands for Sort, Set in Order, Shine, Standardize, Sustain, and Safety.

- Sort: This step involves removing unnecessary items from the workplace to reduce clutter and improve efficiency.

- Set in Order: It focuses on organizing the remaining items in a logical and efficient manner, making it easy to find and access them when needed.

- Shine: This step involves cleaning and maintaining a high level of cleanliness in the workspace to improve safety and productivity.

- Standardize: It involves developing and implementing standard operating procedures and guidelines to ensure consistency and uniformity in the workplace.

- Sustain: This step focuses on ensuring that the 6S practices are continued and maintained in the long term. Regular audits, training, and employee engagement are required to sustain the improvements.

- Safety: It emphasizes the identification and elimination of potential hazards, ensuring workplace safety for employees.

A 6S checklist acts as a tool for employees to evaluate and implement these steps systematically, ensuring that all aspects of workplace organization, cleanliness, and efficiency are addressed. It helps in promoting a more organized and efficient work environment, reducing waste, improving safety, and increasing overall productivity.

What information must be reported on 6s checklist?

The specific information that must be reported on a 6s checklist may vary depending on the organization and its specific procedures. However, a typical 6s checklist should include the following information:

1. Date: The date on which the checklist is being completed.

2. Area/Location: The specific area or location where the 6s process is being implemented.

3. Item/Area Identification: Identification or labeling of the items or areas being assessed.

4. Sort (Seiri): Whether the area has been cleared of unnecessary items, and if any corrective actions are needed.

5. Set in Order (Seiton): Whether items are properly organized, labeled, and stored in designated locations.

6. Shine (Seiso): The cleanliness of the area and whether it meets established standards.

7. Standardize (Seiketsu): Whether standard operating procedures are in place and being followed.

8. Sustain (Shitsuke): The effectiveness of ongoing efforts to maintain the 6s system.

9. Audit/Assessment: Any additional notes or comments from the person conducting the checklist.

10. Corrective Actions/Improvements: Any identified issues or problems with suggested corrective actions.

11. Name/Signature: The name and signature of the person responsible for completing the checklist.

These are general guidelines, and organizations may have additional requirements or specific details to be included in their 6s checklist based on their unique needs and processes.

How do I modify my 6s checklist template excel in Gmail?

Using pdfFiller's Gmail add-on, you can edit, fill out, and sign your 6s audit checklist manufacturing and other papers directly in your email. You may get it through Google Workspace Marketplace. Make better use of your time by handling your papers and eSignatures.

How can I modify 6s checklist for plants without leaving Google Drive?

pdfFiller and Google Docs can be used together to make your documents easier to work with and to make fillable forms right in your Google Drive. The integration will let you make, change, and sign documents, like 6s checklist for manufacturing, without leaving Google Drive. Add pdfFiller's features to Google Drive, and you'll be able to do more with your paperwork on any internet-connected device.

How do I complete lean 6s checklist on an Android device?

Use the pdfFiller mobile app to complete your 6s template on an Android device. The application makes it possible to perform all needed document management manipulations, like adding, editing, and removing text, signing, annotating, and more. All you need is your smartphone and an internet connection.

Fill out your 6s audit checklist form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

6s Warehouse Checklist is not the form you're looking for?Search for another form here.

Keywords relevant to 6s audit

Related to 6s audit template excel

If you believe that this page should be taken down, please follow our DMCA take down process

here

.