Vsi crusher s

- 1. VSI Sand Making Machine CRUSHING | GRINDING | QUARRY PLANT | SCREENING | WASHERS | FEEDING | CONVEYOR Shanghai Joyal Mining Machinery Co., Ltd. Email: joyal@crusherinc.com http://www.joyalcrusher.com

- 2. Email: joyal@crusherinc.com VSI http://www.joyalcrusher.com The JOYAL VSI Crusher is improved on the basis of Germany high technology, which is highly-efficient and superior in performance. The JOYAL VSI Crusher (sand making machine) is widely used to produce sand and stone for highway, high-speed railway, city project, hydropower dam constructions, and concrete mixing plant, and it’s also widely used in sand making and stone reshaping industry.

- 3. Email: joyal@crusherinc.com http://www.joyalcrusher.com Features VSI Crushers the latest research results basing on Germany technology 1. The oil needed is supplied by two oil pumps, and the machine stops automatically if there is no oil; the motor can be heated automatically in winter to ensure the normal working of the machine. 5. Special feeding structure; rock on rock, and rock on iron to make the stones crushed and reshaped. 6. Unique dustproof seal 2. Hydraulic lifting system to check and replace the spare parts, thus it’s very easy and simple to maintain. system to prevent the dust getting into the spare parts. 7. Unique design of 3. The bearing is of SKF and TIMKEN brand to ensure the normal working of the machine. 4. Unique vibrating alarm device: if the machine works abnormally, the alarm will sound to stop the machine, thus protecting the whole machine. material bumping angle reduces the friction between raw material and spare parts, extending the working life of spare parts and cut the cost.

- 4. Email: joyal@crusherinc.com http://www.joyalcrusher.com Working Principle – Center Feeding: Raw materials fall down into the feeding hopper, then enters the impellor through central entrance inlet, thus the material being accelerated by the high-speed impellor and being thrown out at the speed of 60-75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet. – Ring Feeding: Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the impellor through the center of the plate and the other part of materials falls down from outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

- 5. Email: joyal@crusherinc.com Model http://www.joyalcrusher.com VSI-7611 VSI-8518 VSI-9526 VSI-1140 120-180 200-260 300-380 450-520 60-90 100-130 150-190 225-260 35 40 45 50 30 35 40 45 Rotation Speed(rpm) 1700-1890 1520-1690 1360-1510 1180-1310 Double Motor Power (KW) 110 180 264 400 3700×2150×2100 4140×2280×2425 4560×2447×2778 5000×2700×3300 7.8 10.3 16 25.6 Center and Sides Capacity Feeding (t/h) Center Feeding Soft Max. Feeding Material Size (mm) Hard Material Overall Dimension L×W×H (mm) Weight (t) Vibrating Sensor Inspection Range: 0.1-20mm/s continual adjustment Motor Power of Double Oil 2×0.31KW Pump(KW) Hydraulic Overall Oil Pump Dimension 820×520×1270 L×W×H (mm) Power of Oil Tank Heater 2KW

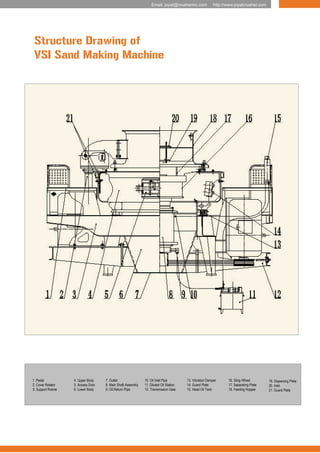

- 6. Email: joyal@crusherinc.com http://www.joyalcrusher.com Structure Drawing of VSI Sand Making Machine 1. Pedal 2. Cover Rotator 3. Support Rrame 4. Upper Body 5. Access Door 6. Lower Body 7. Outlet 8. Main Shaft Assembly 9. Oil Return Pipe 10. Oil Inlet Pipe 11. Diluted Oil Station 12. Transmission Gear 13. Vibration Damper 14. Guard Plate 15. Head Oil Tank 16. Sling Wheel 17. Separating Plate 18. Feeding Hopper 19. Dispersing Plate 20. Inlet 21. Guard Plate

- 7. Email: joyal@crusherinc.com GLOBAL MARKET LEADER IN CRUSHING TECHNOLOGY http://www.joyalcrusher.com

- 8. Email: joyal@crusherinc.com http://www.joyalcrusher.com Add: No.3389, East Huaxia Road, Pudong New Area, Shanghai, China. Email: joyal@crusherinc.com Tel: 0086-21-68763311 0086-21-68763366 Web: http://www.joyalcrusher.com